Technical Center Fineblanking Tool Project

We are very pleased to announce a successful project with the “Arbeitskreis Feinschneiden” a workgroup initiated by the Laboratory for Machine Tools and Production Engineering (WZL) of the RWTH Aachen University, Germany, as a strategic research network for international and innovative companies in the fineblanking sector.

The project’s focus was to test the effectiveness (wear resistance) of using tungsten carbide material for the active cutting elements to fineblank high-strength steel.

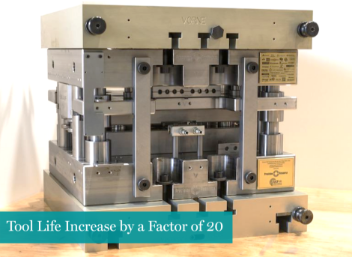

In cooperation with the team of the WZL our Technical Center in Cambridge, Ontario, Canada had completely redesigned the fineblanking tool to ensure exact and rigid position of the active cutting elements, which is essential for blanking with carbide cutting components.

The new tool design was a result of completing a comprehensive review of all tool-related influences that could cause a premature failure of the blank punch. This task was accomplished with support and additional recommendations from our experienced team in Canada.

The tool’s design was brought to life as each and every element was 100% manufactured, assembled and tested at out Technical Center and parameters optimized at our Canadian Production facility using our Feintool XFT 2500 Speed Servo Press before it was sent to the WZL team in Germany.

The new tool was then handed over to the WZL team of the RWTH Aachen University for a series of tests using scientifically developed methods on their equivalent XFT 2500 servo press. After process control was optimized the tool made a series of 10,000 strokes with carbide and conventional HSS punches.

The test results specifically compared the wear characteristics of carbide to conventional HSS (high-speed-steel) cutting components. The conventional HSS cutting components was almost at the end of its service life while the carbide showed little to no wear, thereby increasing tool life by a factor of 20.

On behalf of Precision Resource, we would like to extend our sincere thanks and gratitude to everyone who was involved in this successful collaboration and project. As we are committed to support the advancement of fineblanking technology and innovation, we look forward to support more future projects.

To learn more about the project and the Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, please visit: https://www.wzl.rwth-aachen.de/ca/f/jxlwk/